-

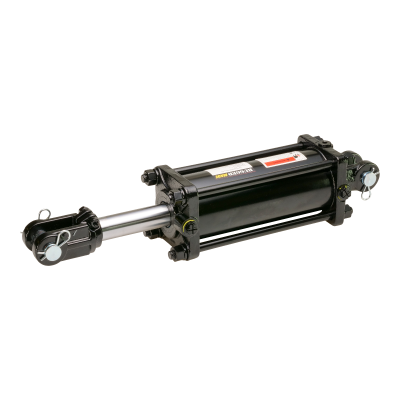

Log Splitter Cylinder: Welded, Clevis, 4" Bore, 24" Stroke, 2.25" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-4024225

Log Splitter Cylinder: Welded, Clevis, 4" Bore, 24" Stroke, 2.25" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-4024225 -

Log Splitter Cylinder: Welded, Trunnion, 4" Bore, 24" Stroke, 2.25" Rod, NPTSKU: 34-153-CYLN-05-225

Log Splitter Cylinder: Welded, Trunnion, 4" Bore, 24" Stroke, 2.25" Rod, NPTSKU: 34-153-CYLN-05-225 -

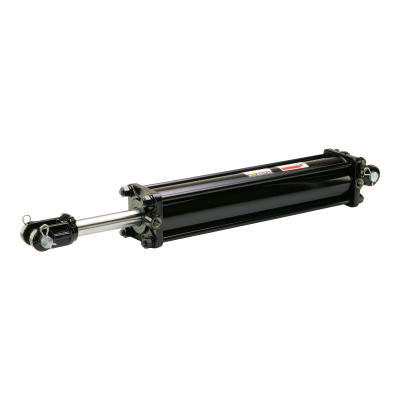

Log Splitter Cylinder: Welded, Clevis, 4.5" Bore, 24" Stroke, 2.25" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-4524225

Log Splitter Cylinder: Welded, Clevis, 4.5" Bore, 24" Stroke, 2.25" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-4524225 -

Log Splitter Cylinder: Welded, Clevis, 4.5" Bore, 24" Stroke, 3" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-4524300-2375-CL

Log Splitter Cylinder: Welded, Clevis, 4.5" Bore, 24" Stroke, 3" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-4524300-2375-CL -

Log Splitter Cylinder: Welded, Clevis, 4.5" Bore, 30" Stroke, 3" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-4530300-2375-CL

Log Splitter Cylinder: Welded, Clevis, 4.5" Bore, 30" Stroke, 3" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-4530300-2375-CL -

Log Splitter Cylinder: Welded, Clevis, 5" Bore, 24" Stroke, 3.5" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-5024350-2375-CL

Log Splitter Cylinder: Welded, Clevis, 5" Bore, 24" Stroke, 3.5" Rod, NPT, 1.25" PinSKU: 34-153-CYLN-5024350-2375-CL -

-

-

Top Link Cylinder: Welded, Swivel Ball, 2.5" Bore, 10" Stroke, 1.5" Rod, ORB, 0.75" PinSKU: 34-153-TL30251012

Top Link Cylinder: Welded, Swivel Ball, 2.5" Bore, 10" Stroke, 1.5" Rod, ORB, 0.75" PinSKU: 34-153-TL30251012 -

Top Link Cylinder: Welded, Swivel Ball, 3" Bore, 10" Stroke, 1.5" Rod, ORB, 1" PinSKU: 34-153-TL30301012

Top Link Cylinder: Welded, Swivel Ball, 3" Bore, 10" Stroke, 1.5" Rod, ORB, 1" PinSKU: 34-153-TL30301012 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Cylinder: Welded, Cross Tube, 1.5" Bore, 16" Stroke, 1" Rod, ORB, 0.75" PinSKU: 34-153-W30151608-CTCT

Cylinder: Welded, Cross Tube, 1.5" Bore, 16" Stroke, 1" Rod, ORB, 0.75" PinSKU: 34-153-W30151608-CTCT -

Cylinder: Welded, Cross Tube, 1.5" Bore, 18" Stroke, 1" Rod, ORB, 0.75" PinSKU: 34-153-W30151808-CTCT

Cylinder: Welded, Cross Tube, 1.5" Bore, 18" Stroke, 1" Rod, ORB, 0.75" PinSKU: 34-153-W30151808-CTCT -

-

-

Cylinder: Welded, Cross Tube, 2" Bore, 8" Stroke, 1.25" Rod, NPT, 90 degrees, 1" PinSKU: 34-153-CYLN-2008125-A

Cylinder: Welded, Cross Tube, 2" Bore, 8" Stroke, 1.25" Rod, NPT, 90 degrees, 1" PinSKU: 34-153-CYLN-2008125-A -

Cylinder: Welded, Cross Tube, 2" Bore, 22" Stroke, 1.25" Rod, ORB, 1" PinSKU: 34-153-W30202210-CTCT

Cylinder: Welded, Cross Tube, 2" Bore, 22" Stroke, 1.25" Rod, ORB, 1" PinSKU: 34-153-W30202210-CTCT -

Cylinder: Welded, Cross Tube, 2" Bore, 22.75" Stroke, 1.25" Rod, ORB, 1.25" PinSKU: 34-153-W30202210-CTCT-ASAE

Cylinder: Welded, Cross Tube, 2" Bore, 22.75" Stroke, 1.25" Rod, ORB, 1.25" PinSKU: 34-153-W30202210-CTCT-ASAE -

Cylinder: Welded, Cross Tube, 2" Bore, 24" Stroke, 1.125" Rod, NPT, 1" PinSKU: 34-153-W30202409-CTCT-ASAE

Cylinder: Welded, Cross Tube, 2" Bore, 24" Stroke, 1.125" Rod, NPT, 1" PinSKU: 34-153-W30202409-CTCT-ASAE -

Cylinder: Welded, Cross Tube, 2.5" Bore, 10" Stroke, 1.5" Rod, ORB, 1" PinSKU: 34-153-W30251012-CTCTOut of stock

Cylinder: Welded, Cross Tube, 2.5" Bore, 10" Stroke, 1.5" Rod, ORB, 1" PinSKU: 34-153-W30251012-CTCTOut of stock -

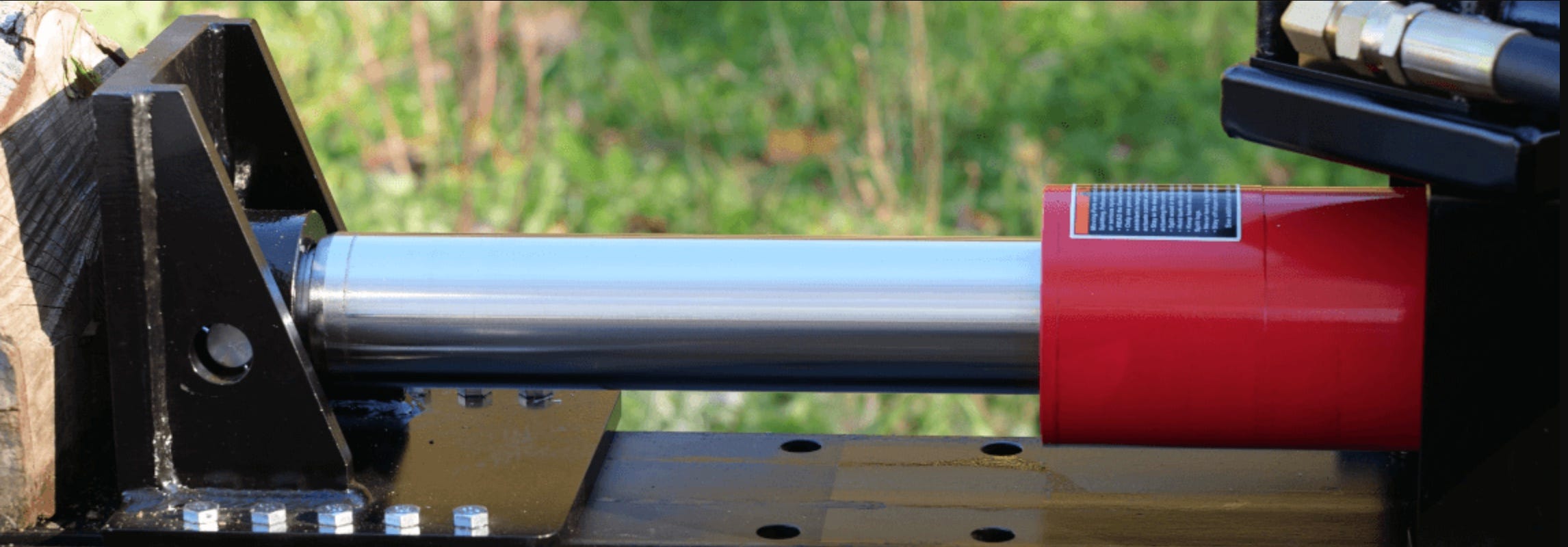

Brawn Meets Beauty RuggedMade Hydraulic Cylinders

Expertly crafted using the highest grade materials, RuggedMade log splitter hydraulic cylinders are real workhorses that will not disappoint. Designed to tackle the toughest jobs in various applications, they are the perfect choice for upgrading or building your own log splitter.

All RuggedMade hydraulic cylinders ship for free, and we have built-in discount pricing based on quantity!

In addition to log splitter cylinders, we offer a wide variety of hydraulic cylinders to meet the specifications of many hydraulic applications, including compact construction equipment, forestry, agricultural implements, transportation equipment, race car lifts, and waste processing. You can choose from welded or tie-rod construction and mounting types, including clevis mounts and cross tube mounts.

Need Help Choosing a Cylinder?

We understand that selecting the right hydraulic cylinder can be daunting. That's why this video is designed with you in mind. We'll walk you through key dimensions and specifications, empowering you to make an informed decision.

Hydraulic cylinders are not a one-size-fits-all solution. They are used in various applications, from scissor lifts to skid steers, tractors, and log splitters, each with unique requirements. This diversity can make finding the right cylinder a challenge. Whether you're a DIY enthusiast or a machine operator, we're here to guide you in choosing the perfect hydraulic cylinder for your project, whether a replacement or a new build.

Learn About RuggedMade Cylinders

At RuggedMade, we know a thing or two about hydraulic cylinders. Having designed some of the best cylinders you'll find on any log splitter, we applied all of that expertise when developing our impressive line of multi-purpose cylinders.

Whether you're shopping for a replacement cylinder or fabricating your own machine, RuggedMade has the right cylinder to get the job done.

High-quality components and outstanding versatility are why the pros turn to RuggedMade hydraulic cylinders. Watch the video to learn more.